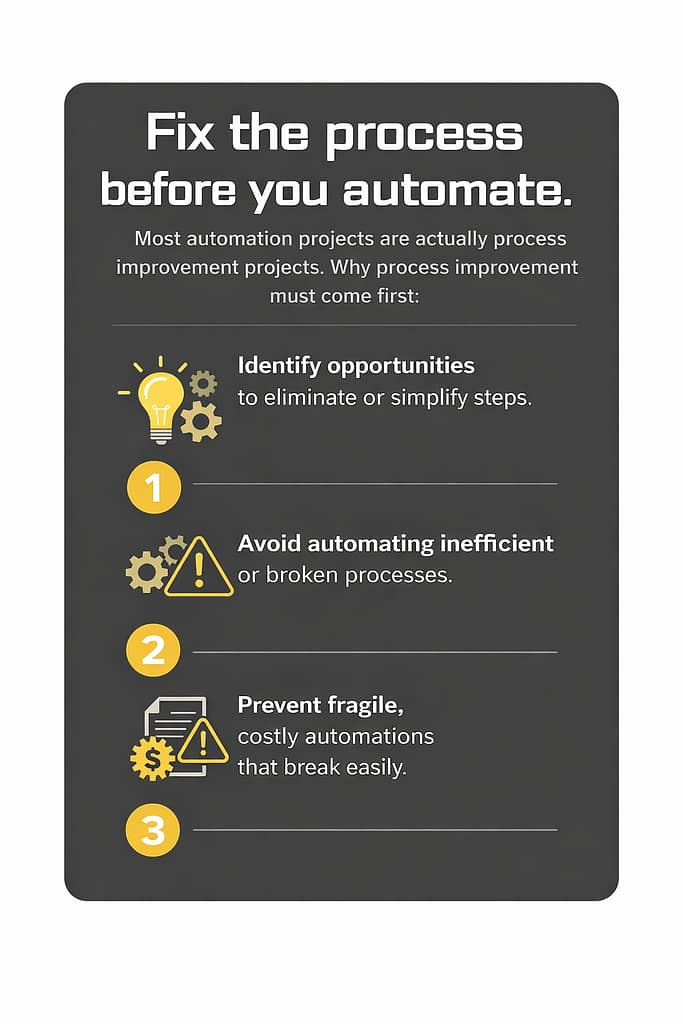

One of the biggest mistakes I see customers making is not recognising that most automation projects are, in reality, process improvement projects.

This can result in:

- Missed opportunities

- Automating poor processes

- Creating fragile automations

The knock on effects are significant:

- You miss opportunities to simplify or remove steps

- You lock in bad behaviour by automating it

- You end up with automations that break as soon as the business evolves

A Real World Example

A recent example of this involved an existing customer. They raised purchase orders against Supplier A, who then passed the work to Supplier B, a sister company. Supplier B subsequently issued the invoice. The customer expected the system to post the invoice to the ERP against Supplier B. However, the original order had been raised against the wrong supplier and in a different currency.

This was not really a problem for automation to solve. It was a process issue that needed to be addressed through changes to ordering ownership, supplier setup and controls, rather than technology.

A business process management tool could then be used to support and enforce the agreed process, providing visibility, governance and exception handling, rather than attempting to compensate for a broken one.

Start With Process Ownership

I always advocate for customers undertaking their own process audits. You do not need fancy process mapping tools or a business process consultant to start mapping as is processes. The first step is always to establish who the process owner is.

The best process owners are often the people doing the process itself. Senior process owners who are not at the coal face often have an understanding of how they think the process works, but it rarely reflects what is actually happening.

Mapping the As Is Process Properly

Completing an as is process mapping exercise allows process owners and stakeholders to agree on what is currently happening. Try not to fall into the common trap of improving the process while mapping it as is.

Make sure the people who actually undertake the tasks are represented in the room, and give everyone the opportunity to voice how they believe things currently work.

Creating Space for Improvement

Allow some time to pass between mapping the as is process and running the improvement workshop. This gives people the opportunity to review the existing process independently and provide feedback.

You may find that additional voices emerge, particularly from those who may not have had the confidence to speak up during the as is mapping workshop.

Challenge the Process Before Automating

Have an independent chair for the improvement workshop and be sure to constantly ask “why”. You will be amazed how often the answer is “we have always done it that way”.

Automation Comes Last

Only once the process has been optimised should you look for automation opportunities and start evaluating which tools you actually need.